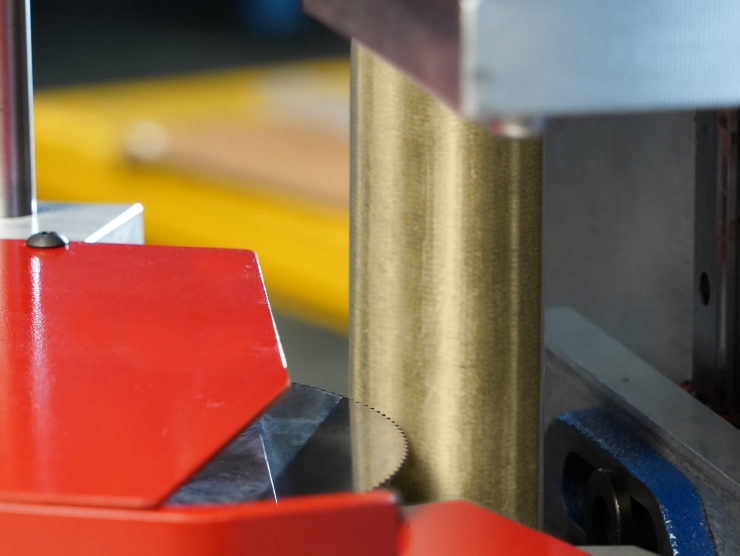

The CC and VCC Series machines are designed for high-performance casting operations in industrial applications, offering highly efficient and reliable equipment. These machines provide excellent quality and precision during the continuous casting of liquid metals. The CC series performs exceptionally well for metals like iron, steel, and aluminum, while the VCC series excels in alloy casting and processes that require high-temperature tolerance.

CC Series Features:

High Efficiency: CC series machines ensure rapid pouring of metal into molds during continuous casting, minimizing energy consumption and enhancing production speed.

Advanced Temperature Control: The CC series machines continuously monitor and control the temperature of the metal. This feature ensures a uniform casting process, resulting in high-quality products with minimal tolerance errors.

Flexibility: Compatible with different metal types and alloys, CC machines offer broad application versatility for various industrial needs.

Durability: Built to withstand high temperatures and heavy workloads, the CC series machines are long-lasting with minimal maintenance requirements.

VCC Series Features:

High-Temperature Performance: VCC machines are made from materials with high thermal resistance, offering a temperature tolerance of up to 1000°C. This feature makes them ideal for alloy casting and operations in demanding production environments.

Precise Casting: VCC machines are capable of producing highly precise casts with minimal tolerance errors, delivering smooth surfaces and flawless products.

Technological Monitoring: Equipped with advanced sensors and monitoring systems, VCC machines ensure that the casting process is continuously controlled, preventing quality losses and ensuring process stability.

In conclusion, the CC and VCC Series machines provide industrial casting solutions that combine quality, efficiency, and durability, delivering high-performance and reliable results for users.